About Us

Unmatched Aluminum Casting & Machining Experience

With a wide range of production capacity and a strong emphasis on customer service, Cast Metals Technology is a non-ferrous casting company with the experience to get the job done right.

Who We Are

Founded in 1992, Cast Metals Technology is focused on customer service as a core component of our casting and machining service offerings. With the flexibility to produce just a few pieces a year for one client and 300,000 pieces a year for another. We are also committed to the safety and well-being of our employees, and to minimizing our impact on the environment through energy-efficient equipment, reuse of materials such as excess foundry sands and aluminum shavings, and pollution control programs.

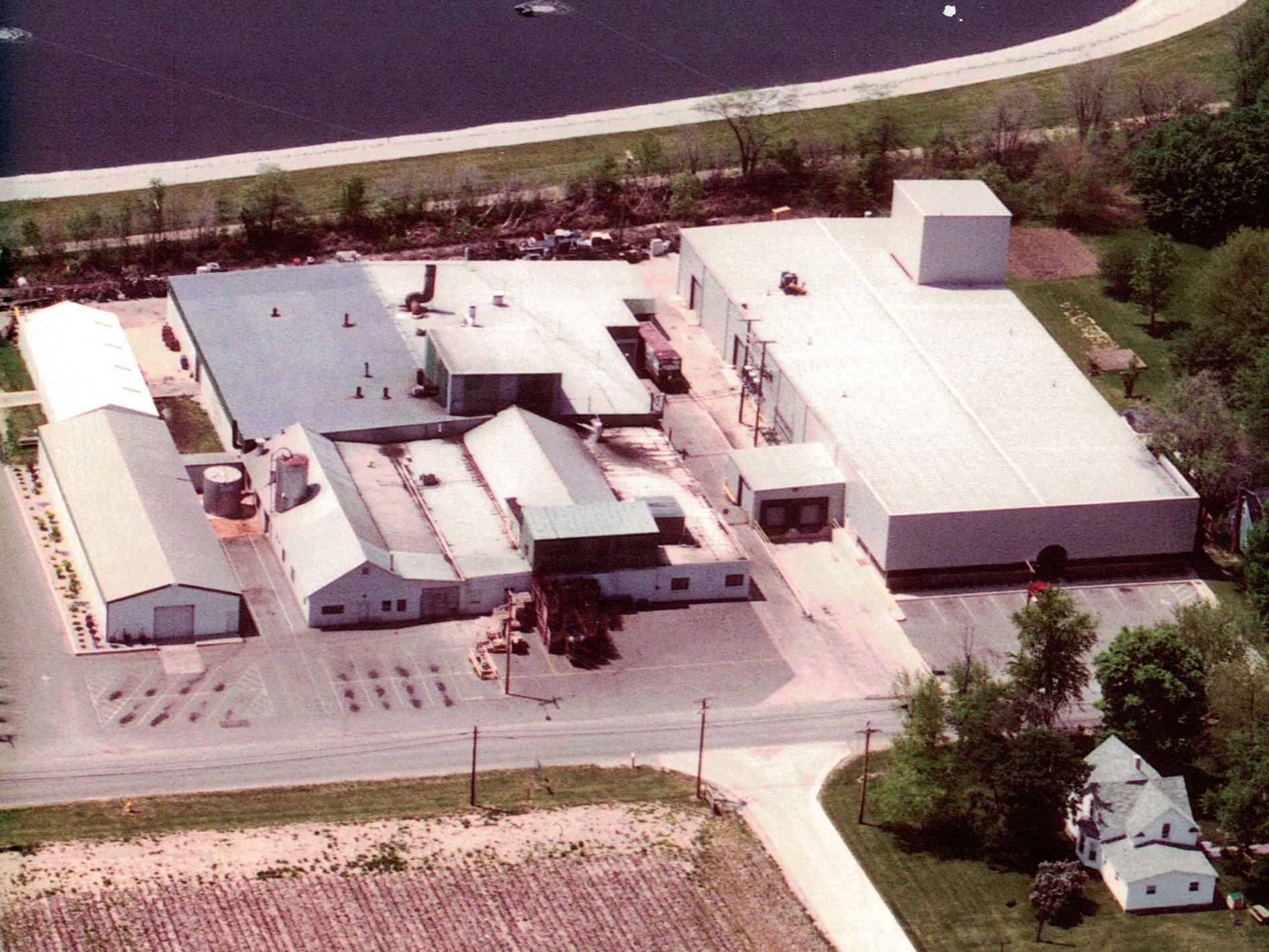

Our Locations

We operate three facilities in Ohio and Indiana. Our facility line-up features locations in:

- Union City, Ohio – low-to medium volume production runs

- Winchester, Indiana – medium- to high volume production runs

- Selma, Indiana – low to high volume machining and assembly work with a variety of specialty equipment

Our Team

Our dedicated employees across three locations allow us to offer the best casting, machining, finishing, and customer service in the industry. Check out our team page to see who makes it all possible!

Learn MoreMedia

See for yourself the equipment we use and the kind of work we’re capable of. Look through our gallery to get a better idea of what we can do for you.

Learn MoreTestimonials

Read what our customers have to say about Cast Metals Technology! Check out our testimonials section.

Learn More

Our History

Cast Metals Technology, Inc. was founded in 1992, after purchasing the assets of Precision Casting Company in Yorktown, Indiana. After significant growth and the need to expand capabilities, in 2005, Cast Metals Technology purchased the assets of Aluminum Foundries, Inc in Winchester, Indiana, which expanded the companies offerings to provide high volume automated sand molding (Hunter 20 & Sinto FB-II) as well as die casting and permanent molding capabilities. Continuing to grow, Cast Metals Technology then expanded its CNC machining capabilities in 2007 by moving its machining capabilities to a 28,000 sf building, allowing the ability to add multiple CNC machining centers including 5 Axis mills and live tool lathes. A few years later as growth continued, it was evident that the low-volume greensand and air-set capabilities needed to be moved to a larger facility. In 2013, Cast Metals Technology purchased the assets of the former Union City Non-Ferrous foundry. This move allowed for additional molding lines and the ability to cast larger parts in air-set.

Cast Metals Technology has continued to focus on adding new technology, equipment and capabilities to improve quality and efficiencies to better serve our customers.

Ready to get started, now that you’re done learning all about us? Get a quote for your project today!